Happy December, internet folk! After a few weeks of tinkering, begging for supplies, doing test prints, whittling and re-engineering, Lilly and I have finally made our first useable letterpressed product- some christmas cards to send to friends and family!

After the fold, you’ll find pictures of the process and all, so click to read on!

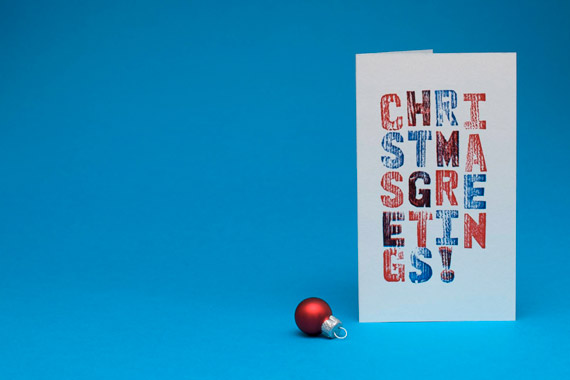

I started with a prototype card, reading ‘Merry Christmastime!’, which came up as a result of Lilly and I trying to think of a christmas greeting as close to 20 letters as possible, as that’s all we can fit in the chase. Somehow we managed to overlook ‘Christmas Greetings!’ first time around, but we liked the result anyway. Foolishly, I put the chase into the press upside down and ended up pressing a dozen Merry Christmastime!s back-to-front, which was a blessing in disguise as a few people found it hard to read, particularly with ME! at the end of it.

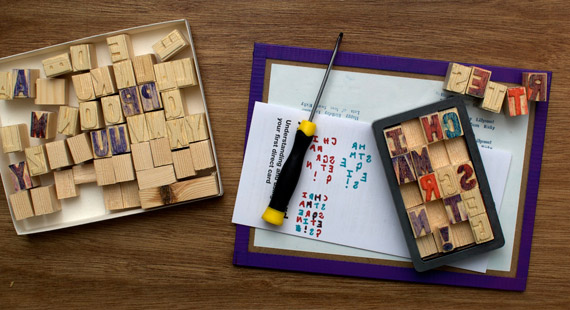

We went back to the drawing board and realised Christmas Greetings! was a much more suitable message, so here is the chase being set up alongside a primitive plan drawn on some scrap paper:

We realised we didn’t have much paper left after the first version’s wastage, so I had a dig around in the fridge and found a random empty sketchbook full of some rather handsome 300gsm paper stock, which I proceeded to trim down to the size we wanted and pre-score. Lilly had a dig around through some of her stuff and found a pack of miniature manilla envelopes she bought once solely because she liked the size of them, which just happened to be a perfect fit (give or take a millimetre) for the cards we made.

And with that, we were pressing! I’m sure this sounds silly to any seasoned letterpresser, but Lilly and I were both pretty amazed by how quickly a job will go after you’ve done all the fiddly setup stuff- I guess this is why the process was invented! Below is a photo of the press in action, in the hands of Lilly. The flash on my camera didn’t fire properly or something, which yielded this photo, managing to look a bit old-fashioned, as letterpressing is!

Here are the cards hanging out to dry after the first colour, on the (surprisingly convenient for this!) wire lights I have above my desk:

We decided to make them more like proper cards and use some real lead type by putting a little credit on the back of the card. The URL on them should link somewhere vaguely here-ish, so if you are friend or family here after receiving a card from us, hello to you and thanks for looking! 🙂

We cleaned up and left them to dry for a couple of days (we haven’t actually worked out how long the ink takes to dry yet, so rather than rushing things, decided it would be best to stay on the safe side), and finally printed the red layer yesterday. Considering how amateur-ish we are (the type was whittled out of softwood by me for goodness sake!) we managed to get the registration pretty good, and where it isn’t, it adds to the design’s whole rustic effect.

So there you have it! It’s quite fun, this letterpress business. Next on the agenda, I think we’ll be getting some designs together and ordering some photopolymer plates from Boxcar as we’ll be in the states for christmas. The tricky part is going to be deciding on what the designs are going to be! That, and hunting out some more lead type. 🙂